Questions to Ask Your Metal Fabricator Before Starting Your Project

Whether you're tackling a commercial build, outfitting a facility, or bringing a custom design to life, choosing the right metal fabricator can make or break your project. Not all fabrication shops are created equal - and the difference between a smooth process and a frustrating one usually comes down to one thing: communication.

Before you hand over your drawings (or ask someone to create them), here are the essential questions to ask your metal fabricator. These will help you understand their capabilities, set expectations, and make sure the team you hire has the skill, experience, and equipment to deliver exactly what you need.

1. What services do you handle in-house?

Metal fabrication can include cutting, bending, forming, machining, welding, powder coating, assembly, and more. Some shops handle everything under one roof. Others outsource parts of the process, which can slow down your timeline and increase costs.

Ask your fabricator:

Do you cut your own materials (laser, plasma, waterjet)?

Do you bend or form metal in-house?

Do you handle machining or specialty processes?

Do you powder coat or finish on-site, or is that outsourced?

At JAMM Fabrication & Design, we’re upfront about what we do in-house because it matters. The more control we have over your project, the tighter the quality, timeline, and consistency.

2. What materials do you work with most?

Steel, stainless steel, aluminum, galvanized metal - each behaves differently and requires specific techniques, tooling, and experience.

A fabricator who specializes in structural steel might not be the best choice for a high-finish architectural railing. A shop that excels in light-gauge sheet metal might not be equipped for heavy industrial work.

Keywords to look for in their answer:

Carbon steel fabrication

Stainless steel fabrication

Aluminum fabrication

Custom machining

Structural fabrication

The right fabricator should know the strengths, limitations, and best uses for each material - not just what they can cut, but what they can cut well.

3. Can you walk me through your quote and project timeline?

A trustworthy fabricator won’t hand you a number without context. A solid quote includes:

Material cost

Labor time

Finishing or coating

Machining or specialty services

Installation, if needed

Expected lead time

If they can’t clearly explain how they arrived at your price or why the timeline is what it is, consider that a red flag. Transparency now prevents surprises later.

4. What tolerances do you work within?

Precision is everything, especially for parts that need to fit, align, or perform under load. Ask about:

Dimensional tolerances

Welding tolerances

Machined part accuracy

Repeatability for bulk production

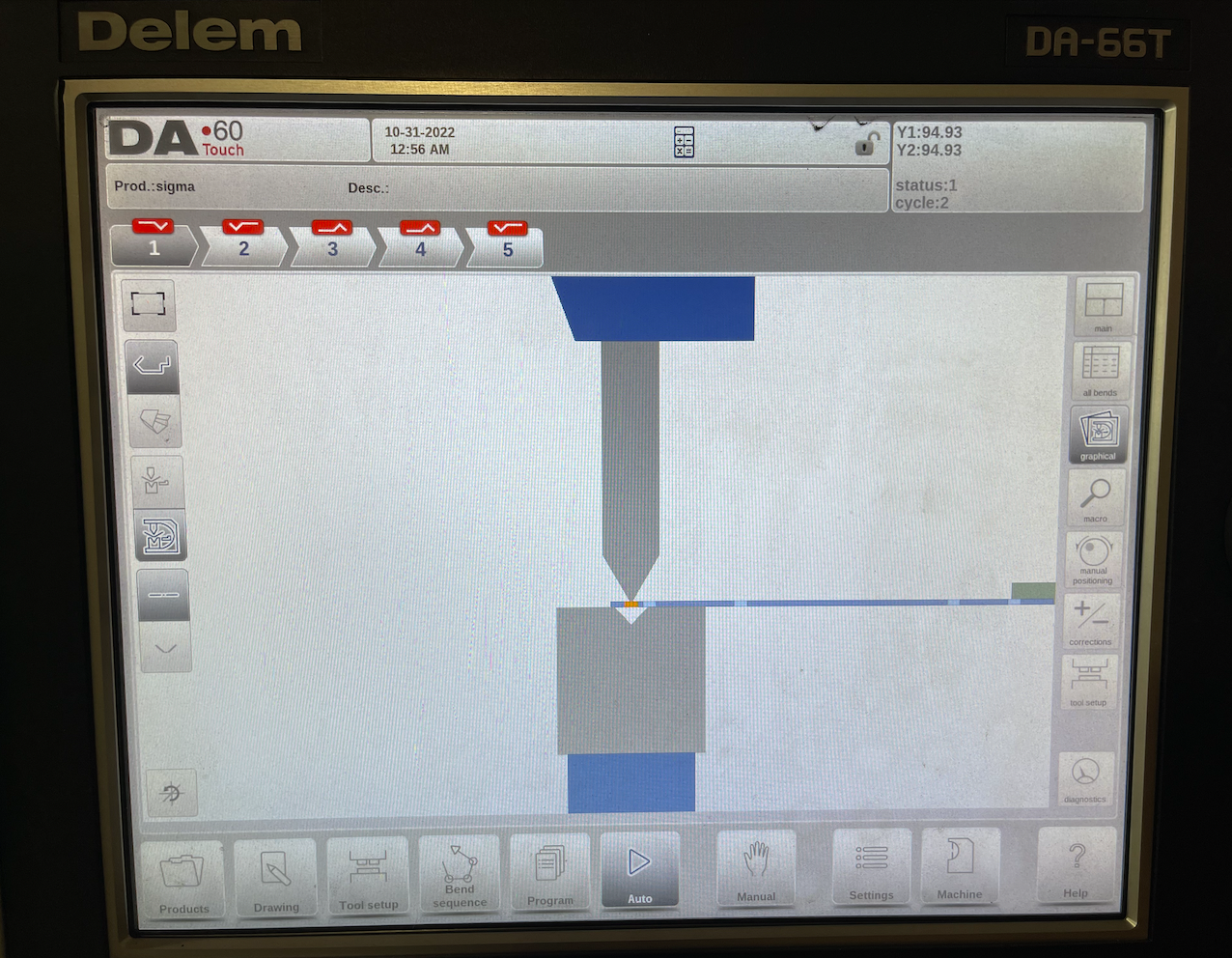

A fabricator who invests in technology like laser cutting, CNC machining, or CMM inspection will have tighter tolerances and cleaner repeatability.

And yes, being “close enough” absolutely matters in metal fabrication. Close enough can cost you alignment, strength, or safety.

5. What quality control steps do you take?

Every shop says they care about quality. The pros can tell you how they measure it. Questions to ask include:

Do you perform inspections throughout the process or only at the end?

Do you document quality checks?

Do you test welds or verify fit?

How do you ensure consistency for large orders?

Shops with real quality standards don’t wait until something goes wrong - they build checks into every stage of fabrication.

6. What does communication look like during the project?

This is one of the biggest differentiators between a smooth fabrication project and a stressful one.

Look for:

A single point of contact

Updates at key milestones

Clear expectations for approval stages

Quick response times

If a shop goes radio silent when you're trying to make a decision, that’s a sign of things to come. You deserve a partner who's as invested in your project’s success as you are.

7. Can I see examples of similar projects?

A reputable metal fabricator should have:

Photos

Videos

Case studies

A shop tour

References (if needed)

The work should speak for itself. If you're investing in custom fabrication, you want a team with proven experience - not someone learning on your project.

8. What do you need from me to get started?

Clear expectations go both ways. Your fabricator may need:

Drawings or 3D models

Material requirements

Finish preferences

Load specifications

Installation details

Project deadlines

The more information you provide upfront, the smoother the entire fabrication process will be.

The Bottom Line

Before you hire a metal fabricator, ask the questions that reveal their experience, capabilities, communication style, and commitment to quality.

At JAMM Fabrication & Design, we believe great work starts with great conversation. When you know what to ask - and your fabricator knows how to answer - you’re already halfway to a project that’s built right.