Why Laser Cutting Is a Game-Changer for Contractors and DIY Designers

In fabrication, accuracy isn’t a luxury. It’s the foundation. A railing that doesn’t line up, a frame that’s a bit off, or a gate hinge that doesn’t fit perfectly can throw an entire project off schedule. Traditional saws and drills have their limits, and even skilled fabricators spend time grinding, adjusting, and recutting to make things fit.

Enter laser cutting. For contractors in Arkansas, designers in Central Texas, or anyone working on projects that demand precision, laser technology has changed the game completely. It’s faster, sharper, and more versatile than older methods, and it’s redefining what fabrication shops can deliver.

What Makes Laser Cutting Different?

Unlike mechanical tools that rely on blades or bits, laser cutting uses a high-powered beam to slice through metal with extreme accuracy. That means:

Unmatched Precision: Cuts measured down to fractions of a millimeter

Cleaner Edges: Smooth finishes reduce the need for grinding or sanding

Repeatability: Every cut is identical, ensuring parts fit perfectly every time

Speed: Faster cutting equals faster project turnaround

For busy contractors or designers who can’t afford delays, that precision and consistency translates directly into savings.

Benefits for Contractors

Contractors know that time is money. On-site adjustments, misaligned holes, and mismatched parts are more than an inconvenience - they’re a profit killer. With tube laser cutting, you can have parts drilled, notched, and cut to spec before they ever reach the job site. That means:

Faster Installations: Components line up perfectly the first time.

Reduced Labor Costs: Less time spent modifying stock materials.

Lower Waste: You only pay for what you need, not leftover material.

Improved Safety: Fewer reworks mean fewer risks on-site.

Contractors across Arkansas and Central Texas are using laser cutting for railings, structural supports, frames, and gates because it streamlines the entire workflow.

Benefits for Designers and DIY Builders

Laser cutting isn’t just for heavy-duty industrial jobs. Designers and DIY builders are leveraging it for creative projects that demand precision and artistry. Decorative panels, signage, and custom furniture pieces benefit from a laser’s ability to cut complex shapes cleanly. Plus, designers aren’t limited to what’s on the shelf - they can bring their own drawings and ideas to life. For DIY builders, working with a local fabrication shop in Arkansas or Central Texas means you can combine your ideas with professional precision.

Seasonal Advantage: Fall and Winter Projects

Laser cutting is especially valuable in fall and winter, when project timelines tighten and weather creates challenges. Contractors can’t afford delays when cold weather is looming, and homeowners want their upgrades ready before the holidays.

By using custom laser-cut parts, jobs move faster and smoother. Railings go up before the first freeze, fencing installs without multiple trips back to the shop, and commercial spaces get upgrades without disrupting business for weeks at a time.

Local Shops, Local Expertise

Working with a local fabrication shop adds another layer of value. Local shops understand regional needs like designing for humid Arkansas winters or dry Texas heat and can deliver parts faster than a distant supplier. That local knowledge makes laser cutting even more effective because you’re getting precision plus insight.

The JAMM Standard in Laser Cutting

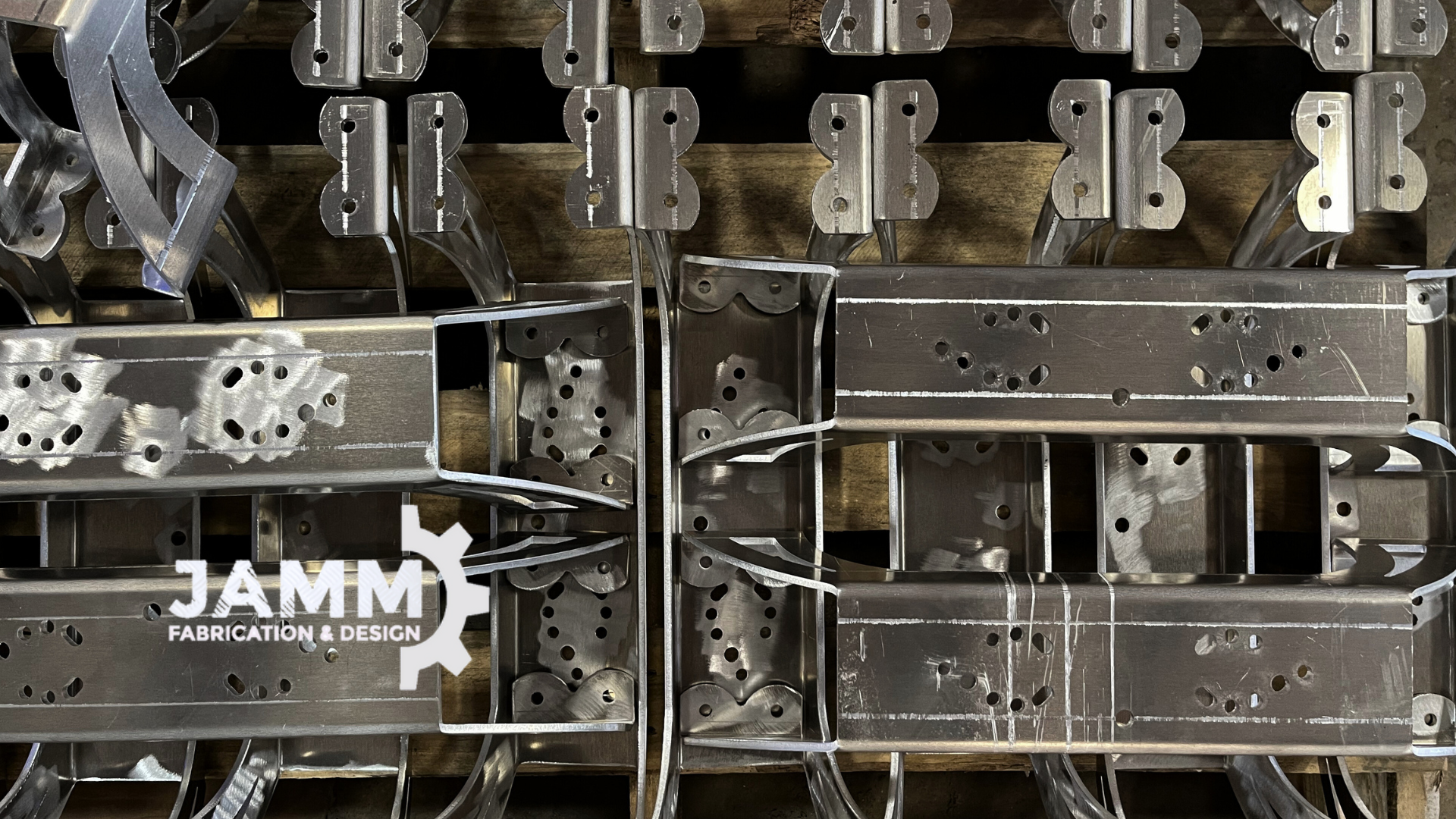

At JAMM Fabrication & Design, laser cutting isn’t just about technology - it’s about standards. Every run is programmed, checked, and re-checked before the first cut. If it’s not perfect, it doesn’t move forward. That’s why contractors and designers trust us with projects that can’t afford to miss.

Closing Thoughts

Whether you’re a contractor bidding your next big project or a designer bringing an idea to life, laser cutting is the tool that makes it possible. Faster, sharper, and more accurate than traditional methods, it turns guesswork into guaranteed fit.

Want your next project cut to perfection? Reach out to us at jammfab.com and let’s make it happen.