What Live Tooling Means for a Fabrication Shop (And Why It Matters for Your Project)

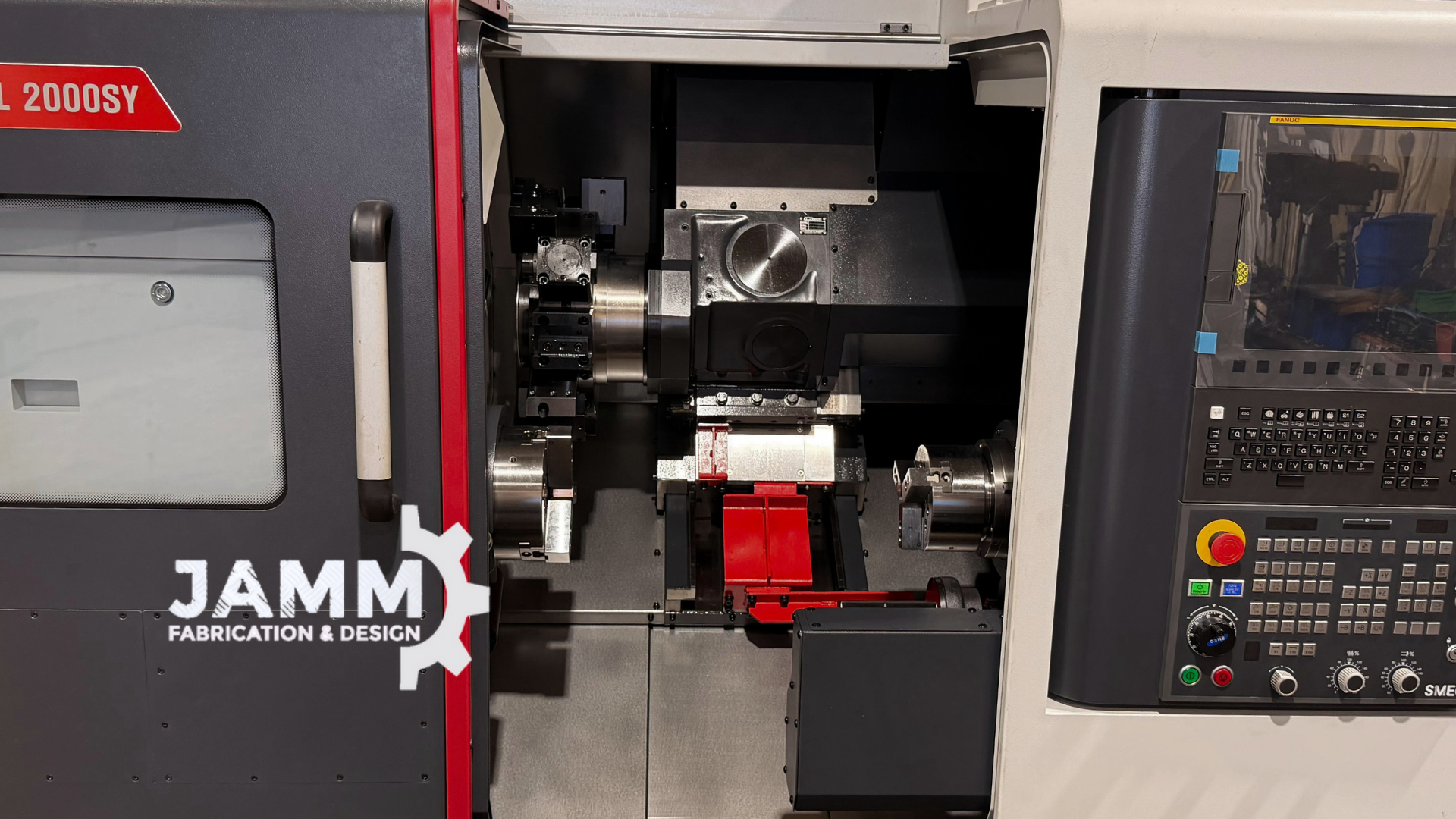

At JAMM Fabrication, we’re always looking for ways to build smarter, faster, and more precisely for our customers. One of the biggest recent upgrades in our Texas shop is the addition of a CNC lathe with live tooling, and while that might sound like shop jargon, it has a real, measurable impact on the quality, cost, and speed of fabrication projects.

So what exactly is live tooling, and why is it such a big deal? Let’s break it down.

What Is Live Tooling?

Traditionally, CNC lathes are designed to spin material while stationary cutting tools shape it. That works great for round parts, but when a component needs holes, slots, flats, keyways, or milled features, the part usually has to move to a second machine, like a mill. Live tooling changes that.

A CNC lathe with live tooling allows cutting tools to rotate while the part is still in the lathe. This means turning, drilling, milling, and tapping can all happen in a single setup, on one machine. In short: more capability, fewer steps, better results.

Why Live Tooling Is a Game-Changer for Fabrication

Fewer Setups = Better Accuracy

Every time a part moves from one machine to another, there’s a chance for small misalignments. Live tooling eliminates unnecessary transfers, which means tighter tolerances, better feature alignment, and more consistent repeatability. For parts that require precision across multiple features, this is a huge advantage.

Faster Production Times

Combining turning and milling operations into one machine dramatically reduces cycle time. Instead of waiting for a part to move through multiple departments, it’s completed in one continuous process.

For customers, that means:

Shorter lead times

Faster turnaround on repeat jobs

More predictable schedules

Speed matters, especially when your project is part of a larger production timeline.

Lower Cost Without Cutting Corners

Efficiency directly impacts cost. By reducing handling, setups, and machine time, live tooling helps control labor and production expenses without sacrificing quality.

That translates to:

More competitive pricing

Fewer surprises mid-project

Better value for complex components

At JAMM, our goal isn’t to rush jobs. It’s to build them efficiently and correctly the first time.

What Types of Projects Benefit from Live Tooling?

Live tooling is especially valuable for complex, high-precision parts commonly used in industrial fabrication and manufacturing environments.

Some examples include:

Shafts with cross-holes or milled flats

Custom bushings and couplings

Brackets and fittings requiring turned and milled features

Components with tight positional tolerances

Parts that need drilling, tapping, and profiling in one operation

For fabrication shops like JAMM, this capability bridges the gap between machining and fabrication, allowing us to support projects from prototype through production. From a customer standpoint, live tooling isn’t just a machine upgrade - it’s a process upgrade.

It means:

Fewer vendors involved

Less back-and-forth between shops

Improved quality control

Better communication from start to finish

When more of the work happens under one roof, we maintain control over quality, timing, and execution.

Live Tooling at JAMM Fabrication

With the addition of our CNC lathe equipped with live tooling, JAMM continues to expand our machining and fabrication capabilities. This investment allows us to take on more complex projects, support tighter tolerances, and deliver consistent results, be it a one-off custom part or a production run.

It’s another step toward what we’ve always focused on: precision, performance, and doing the job right.

Thinking About a Machined or Fabricated Part?

If your project involves complex geometry, tight tolerances, or parts that traditionally require multiple machining steps, live tooling could be the difference between “good enough” and “built to perform.”

Have a drawing? A sample part? Even a rough sketch? We’re happy to walk through it with you and determine the best fabrication and machining approach. Because better tools mean better builds, and better builds mean better outcomes for our customers.